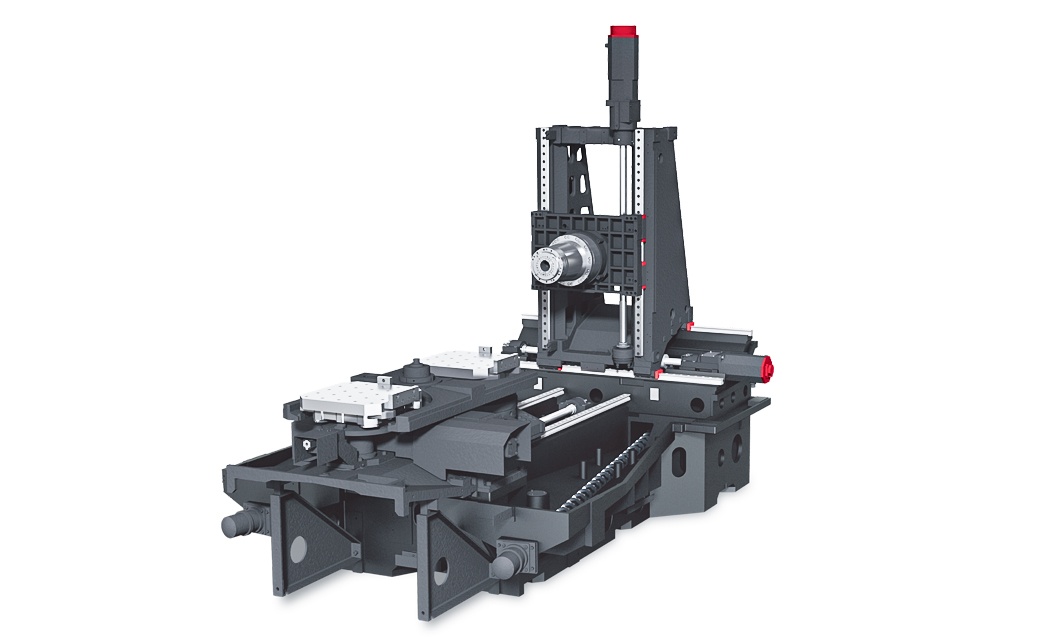

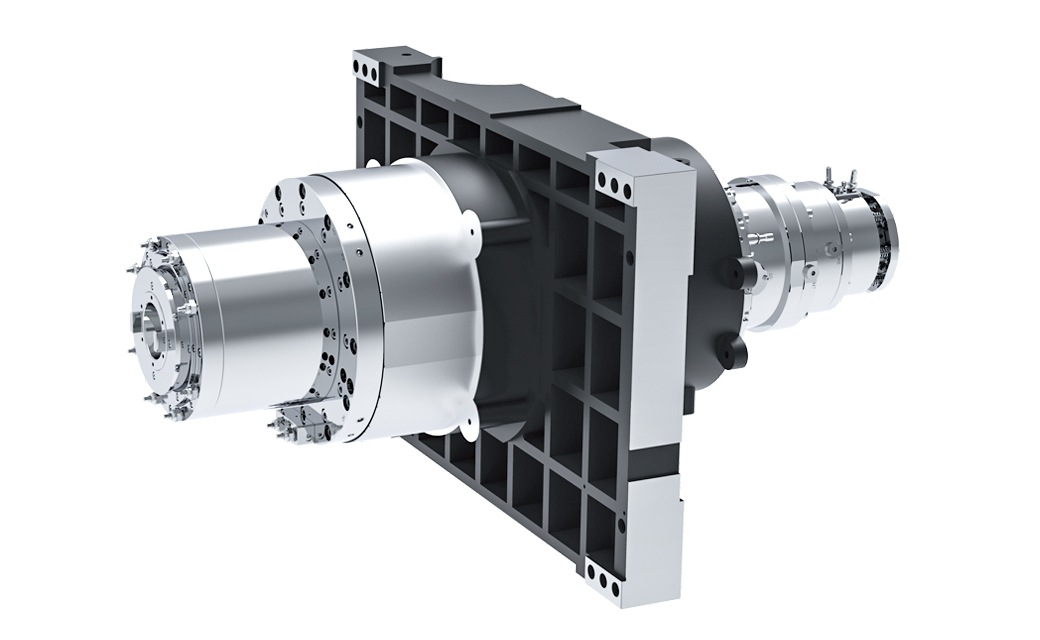

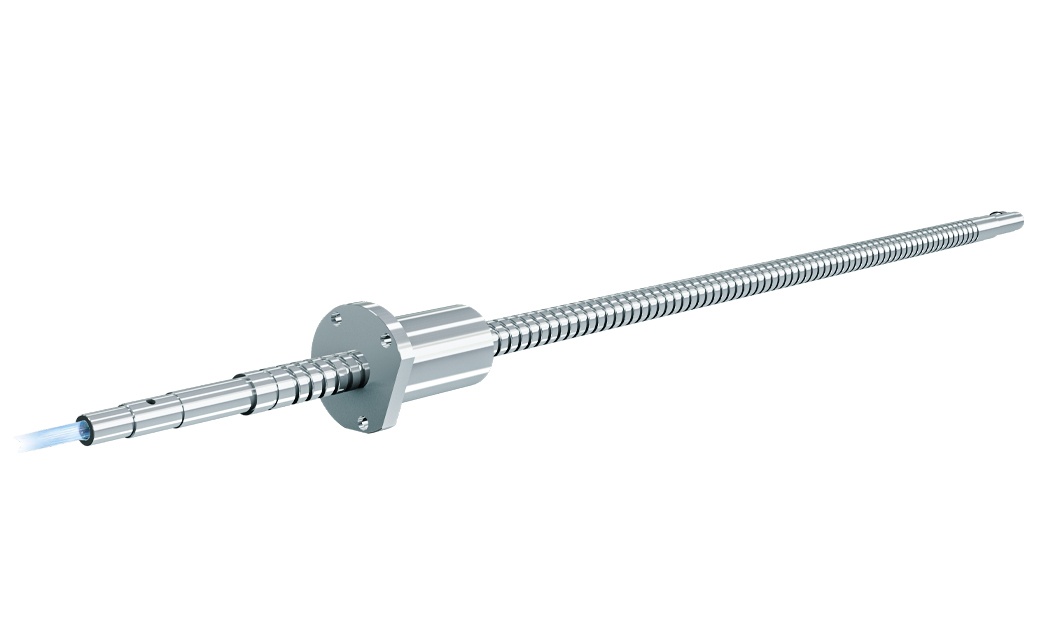

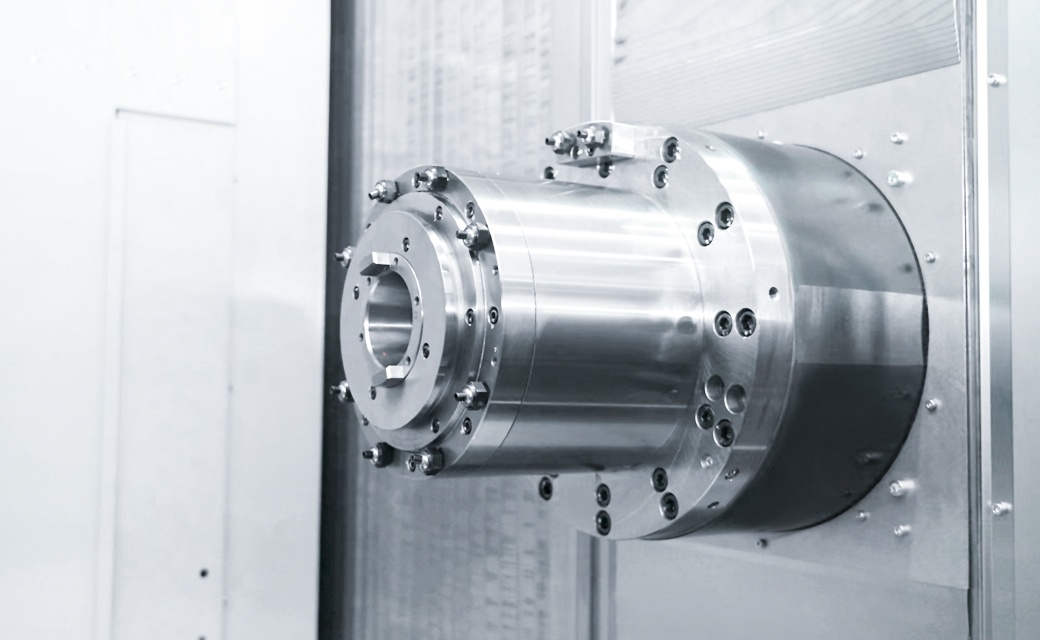

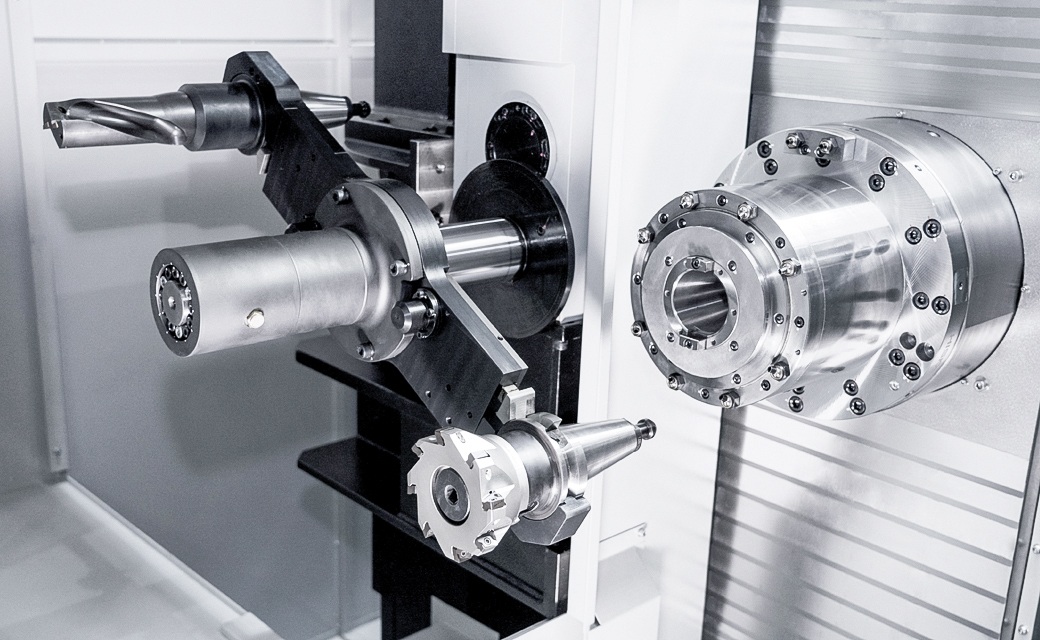

The high precision horizontal machining center boasts superior production performance. Its high-rigidity base structure enables heavy cutting operations. The entire series comes standard with hollow ball screws, ensuring stable machining accuracy. It can be combined with FMS flexible lines for enhanced production capacity. This machining center is widely applicable in fields such as automotive parts, reducer housings, and general industries.

You are currently viewing a placeholder content from YouTube. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More InformationDirect Contact

No matter where you are – our regional sales & service partners are available to answer all your questions.