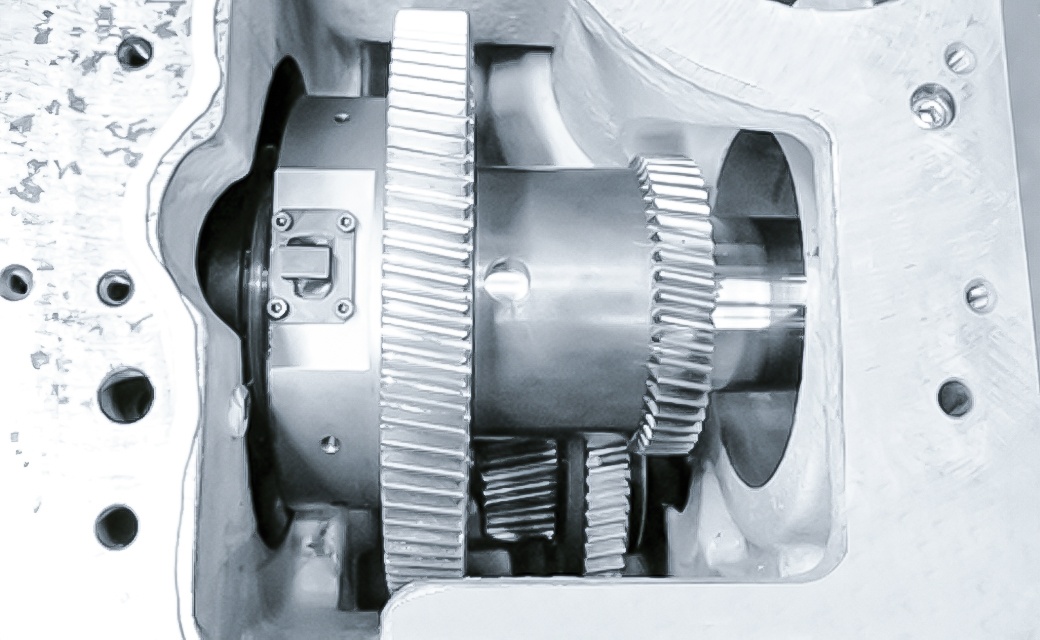

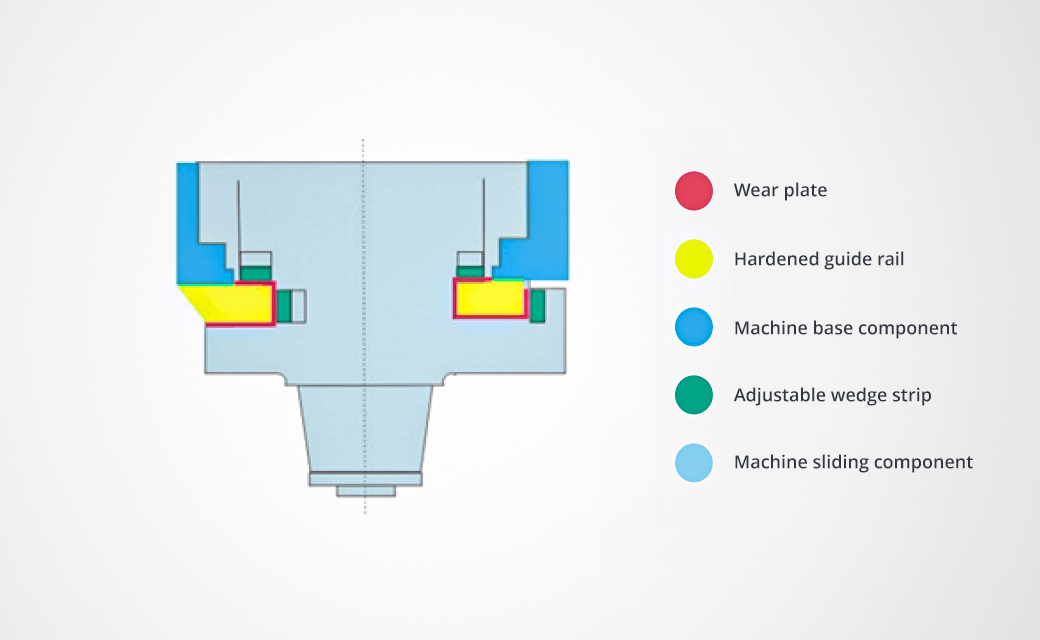

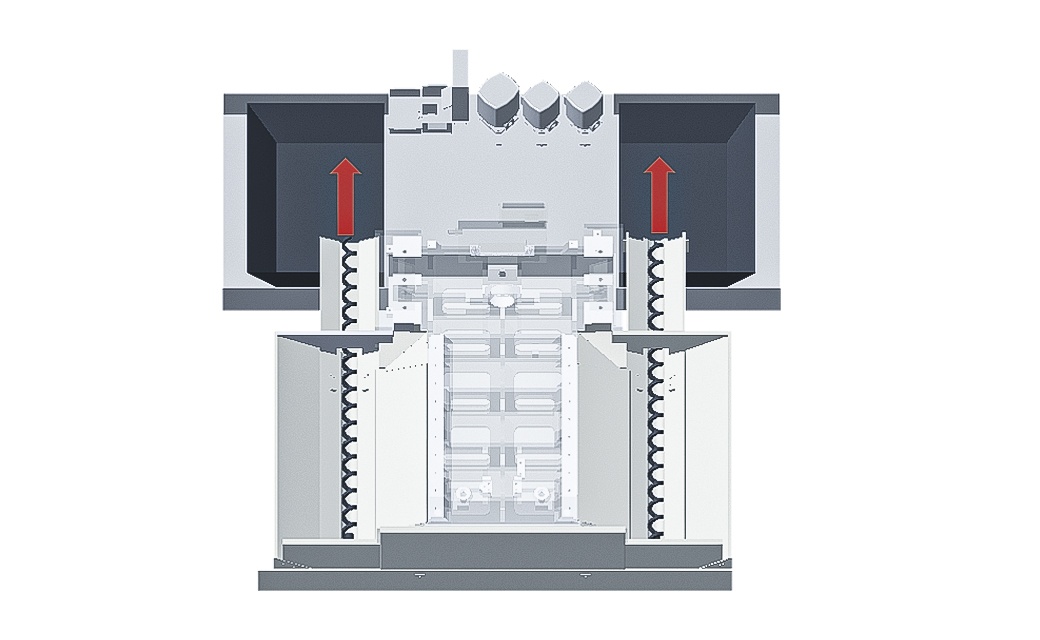

The HII•HII/D Series adopts an advanced T-shaped bed structure, gantry-style column, and front-mounted box layout, providing strong rigidity and high precision retention, suitable for both rough and fine machining of precision-grade box components. Fit for automotive, rail transportation, aviation, valves, mining machinery, textile machinery, plastic machinery, shipbuilding, and power industries.

You are currently viewing a placeholder content from YouTube. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More InformationDirect Contact

No matter where you are – our regional sales & service partners are available to answer all your questions.