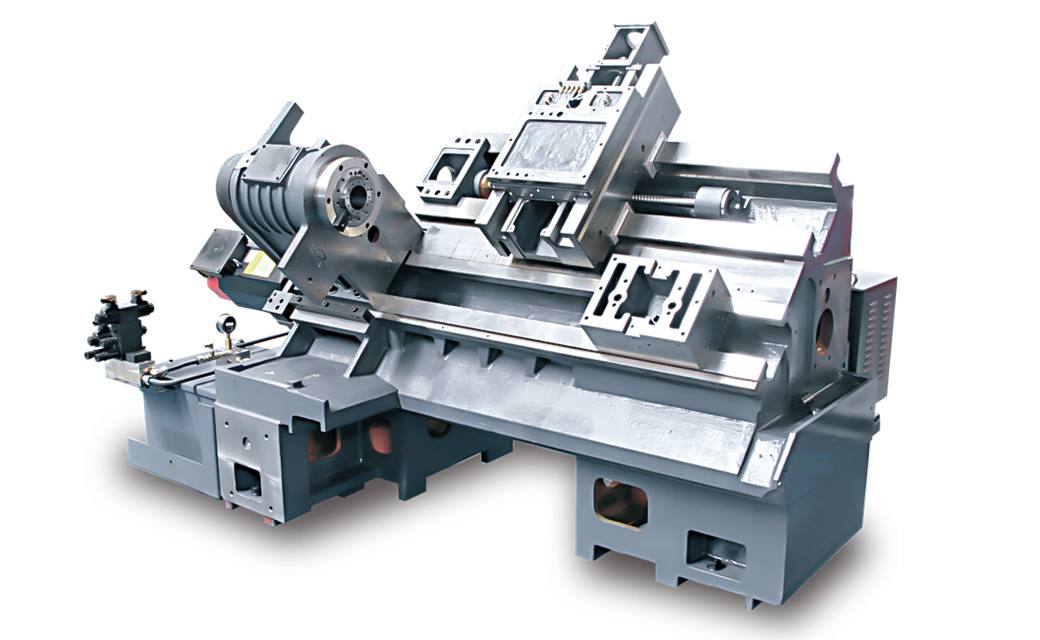

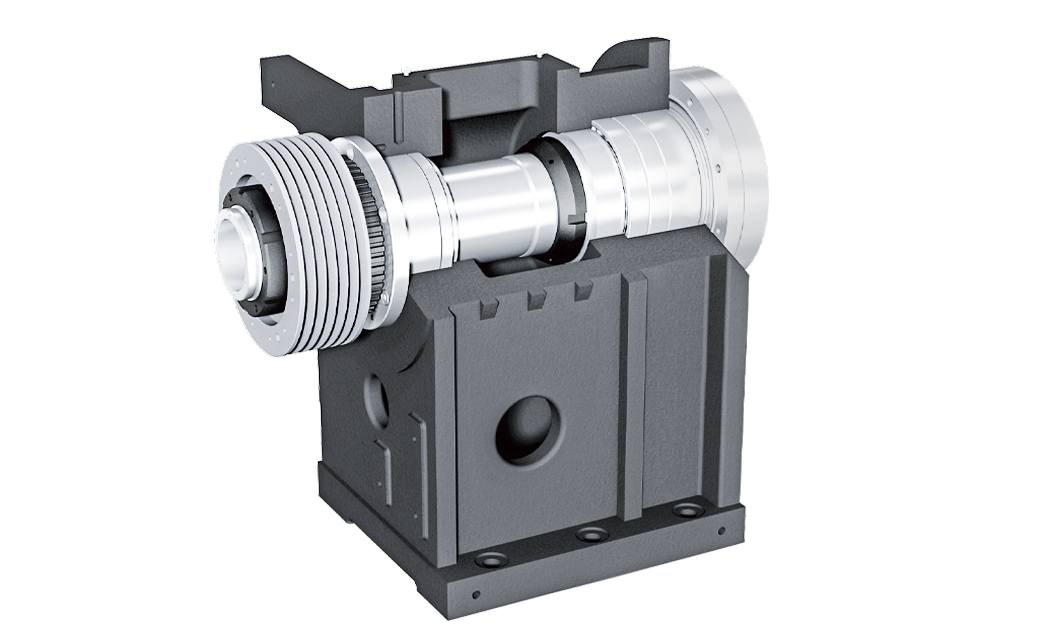

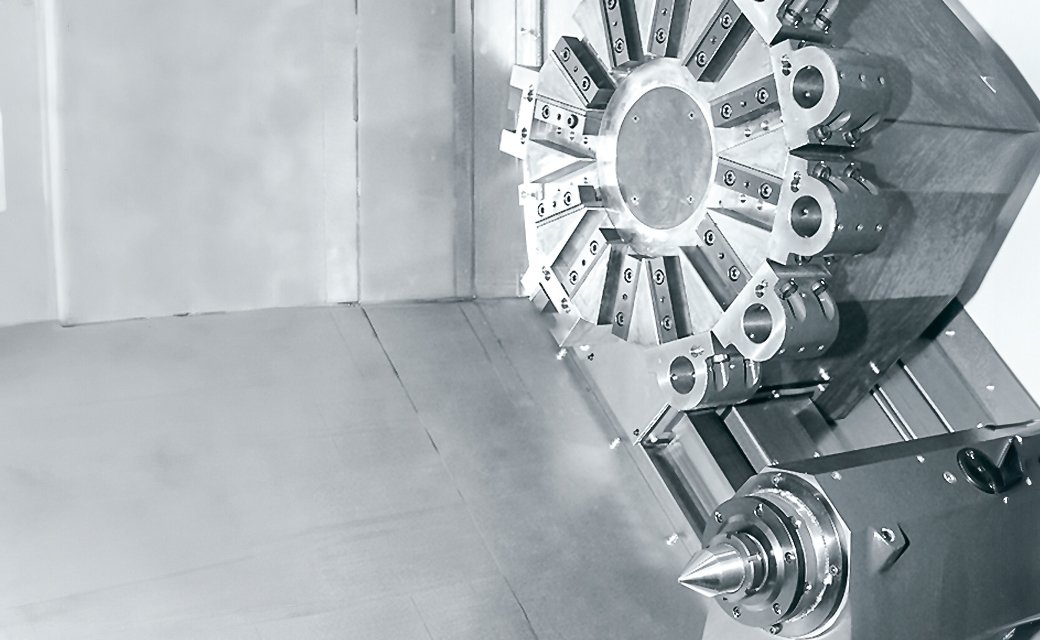

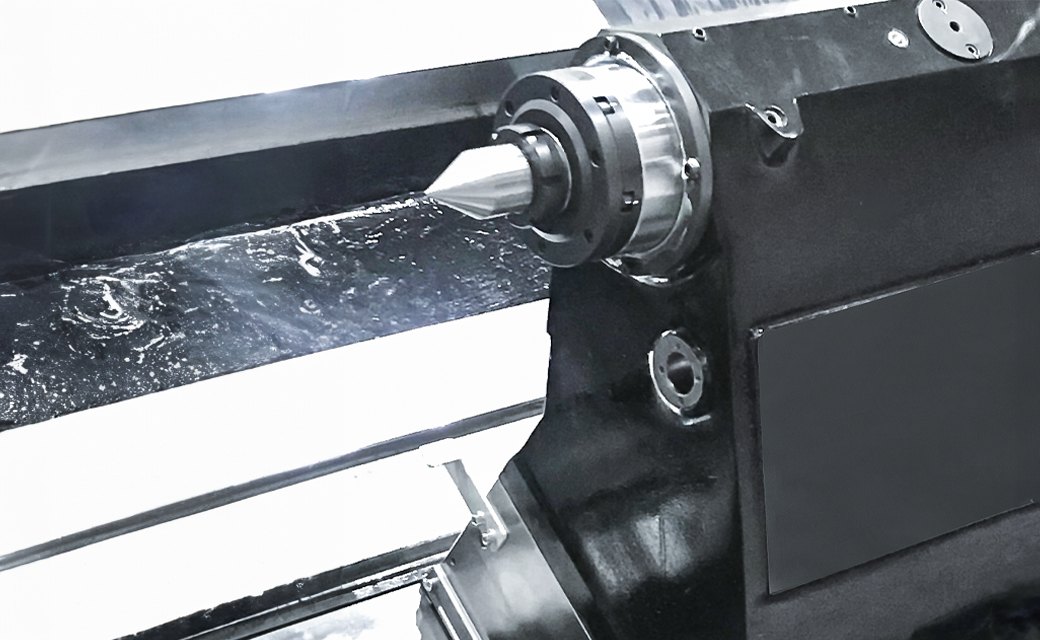

The TC Series features a 45° integrated cast bed structure with hardened and ground guideways. All castings are optimized through finite element analysis, ensuring high precision and stability of the machine tool. Comprehensive automation interfaces and modular automatic protection design provide a foundation for quick automation implementation.

You are currently viewing a placeholder content from YouTube. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More InformationDirect Contact

No matter where you are – our regional sales & service partners are available to answer all your questions.