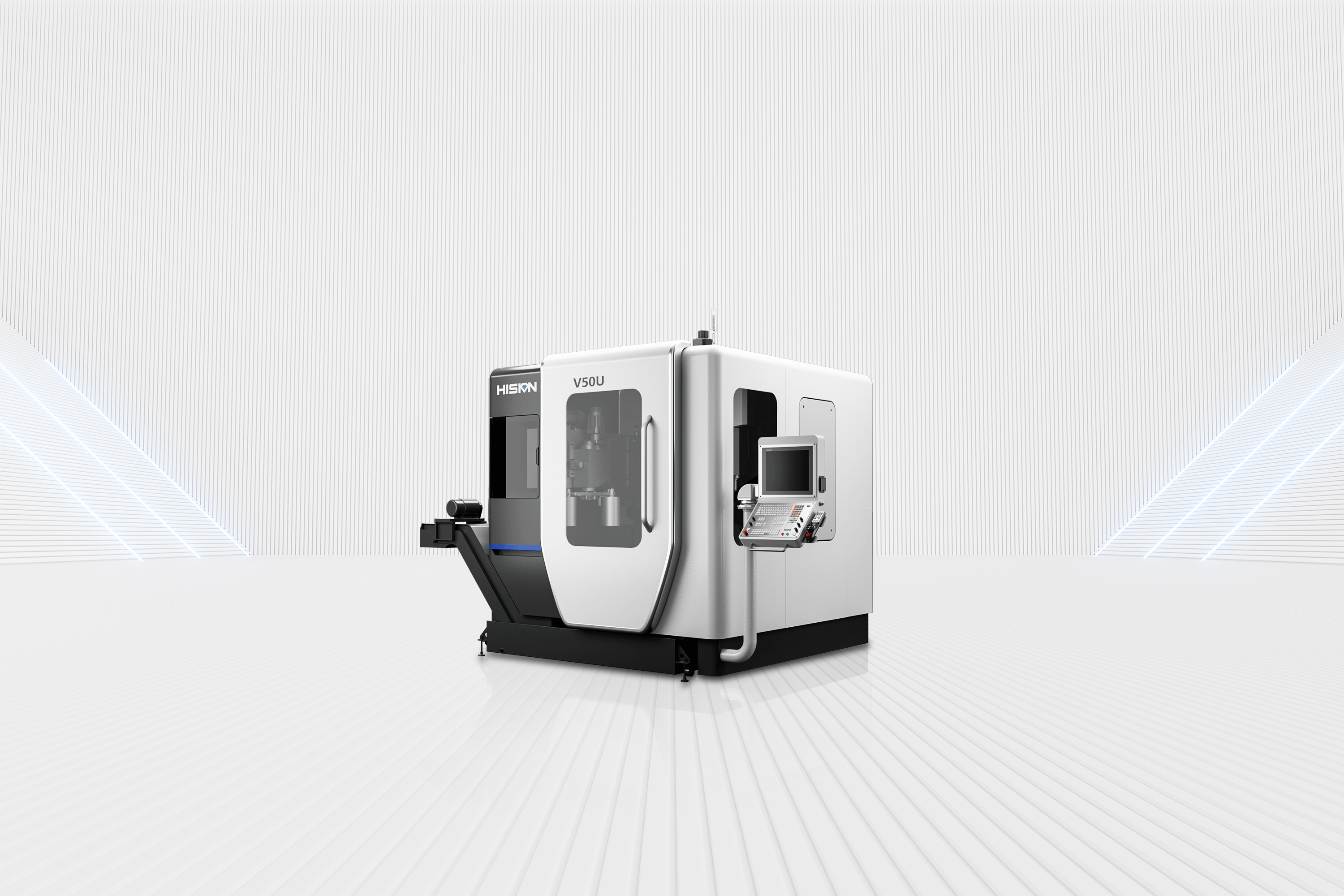

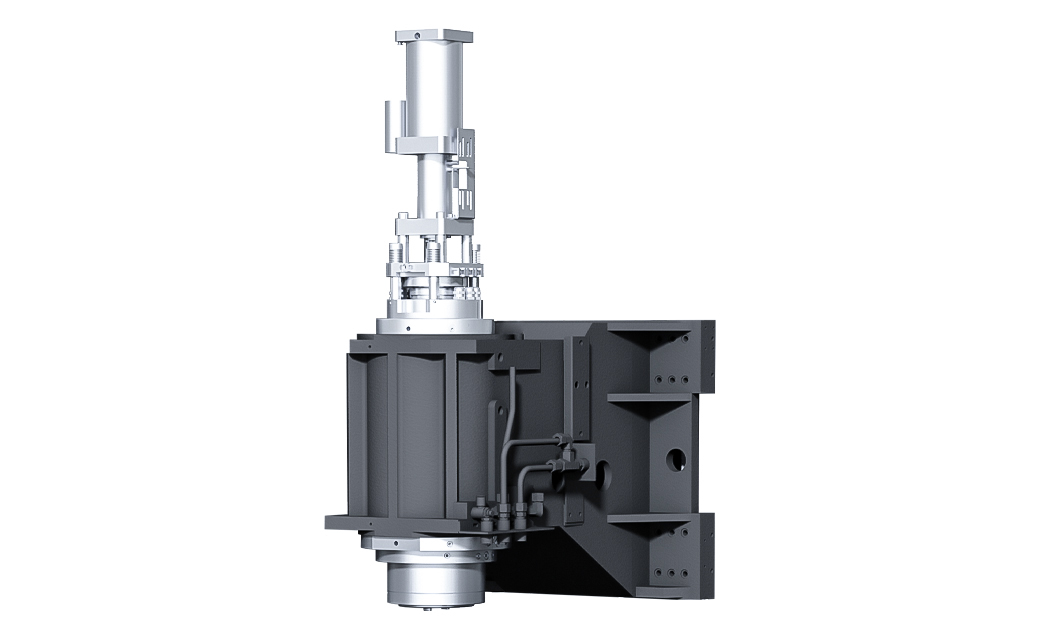

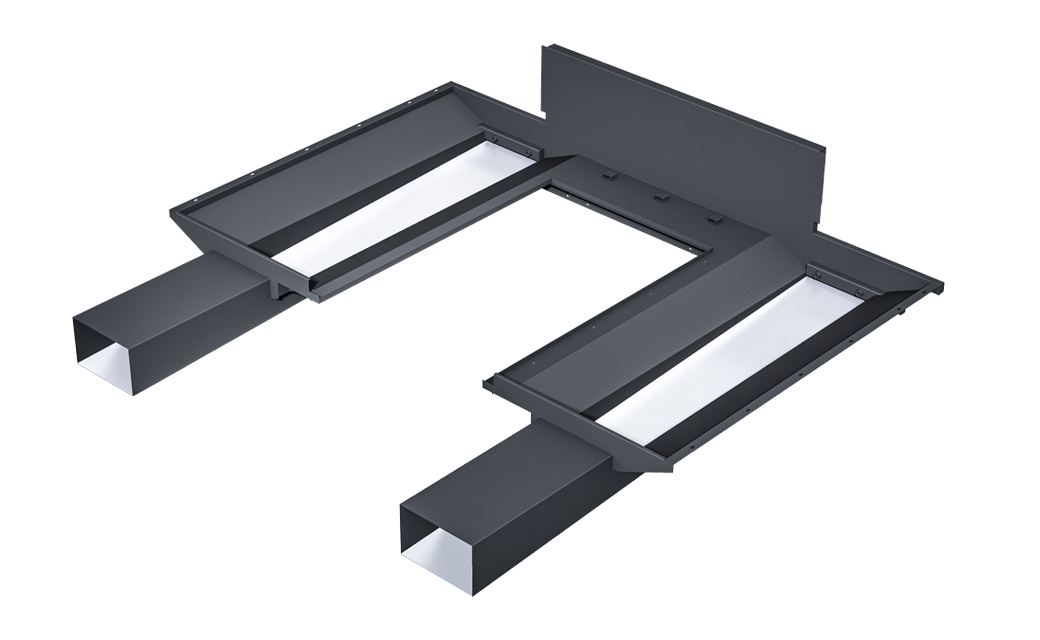

We are excited to present our new 5-axis milling machine, designed for precision, efficiency, and seamless automation. Its ergonomic design and three-sided loading capability ensure flexibility and ease of use, while the maintenance-free coolant tank and advanced chip management guarantee reliable and clean operation. Discover the future of efficient manufacturing

You are currently viewing a placeholder content from YouTube. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More InformationDirect Contact

No matter where you are – our regional sales & service partners are available to answer all your questions.